System Overview: Mass Flow vs. Orifice Flow

- Aug 25, 2025

- 2 min read

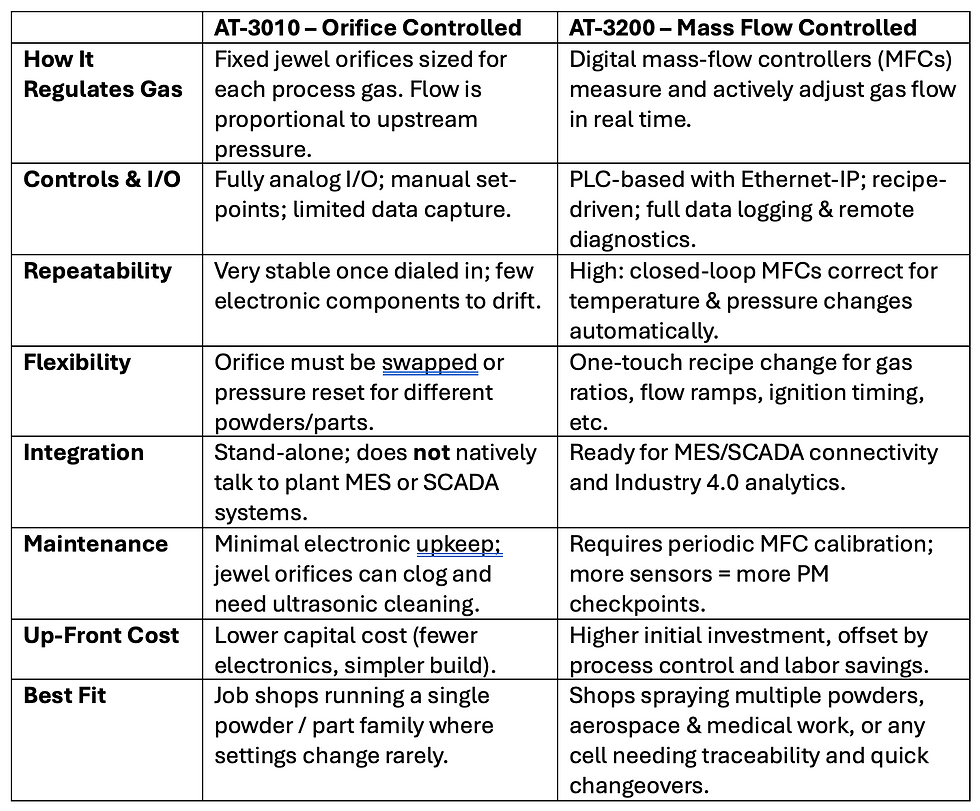

Choosing Between Orifice-Controlled (AT-3010) and Mass-Flow-Controlled (AT-3200) Plasma Spray Consoles

Pros & Cons

AT-3010 (Orifice Controlled)

Pros

Simplicity – operators learn it quickly.

Rock-solid day-to-day repeatability when conditions are constant.

Lower purchase price; fewer electronic spares to stock.

Cons

Adjustments are pressure-based guesses; actual mass flow varies with temperature & supply pressure.

Changing powders often means physical re-plumbing or swapping orifices, increasing downtime.

Limited ability to capture process data or connect to modern automation systems.

AT-3200 (Mass Flow Controlled)

Pros

True mass-flow accuracy (< ±1 % FS) across temperature/pressure swings.

Recipe management slashes setup time—ideal for short runs or multiple spray stations.

Real-time data (flow, voltage, amperage, deposition efficiency) can feed SPC dashboards, quality records, and OEE metrics.

Ready for remote support and predictive maintenance through built-in diagnostics.

Cons

Higher capital cost and more complex calibration requirements.

Sensitive electronics require clean, dry utilities and stable power.

More components mean a steeper learning curve for technicians.

Selection Guide

Key Take-Away

Orifice-controlled systems shine in stable, single-process environments where simplicity and cost control trump flexibility.

Mass-flow-controlled systems excel when you need rapid changeovers, digital traceability, and integration with smart factories.

If you’re still unsure which direction fits your production goals, our applications team can model your part mix and projected payback, or arrange a live demo of both consoles side-by-side.

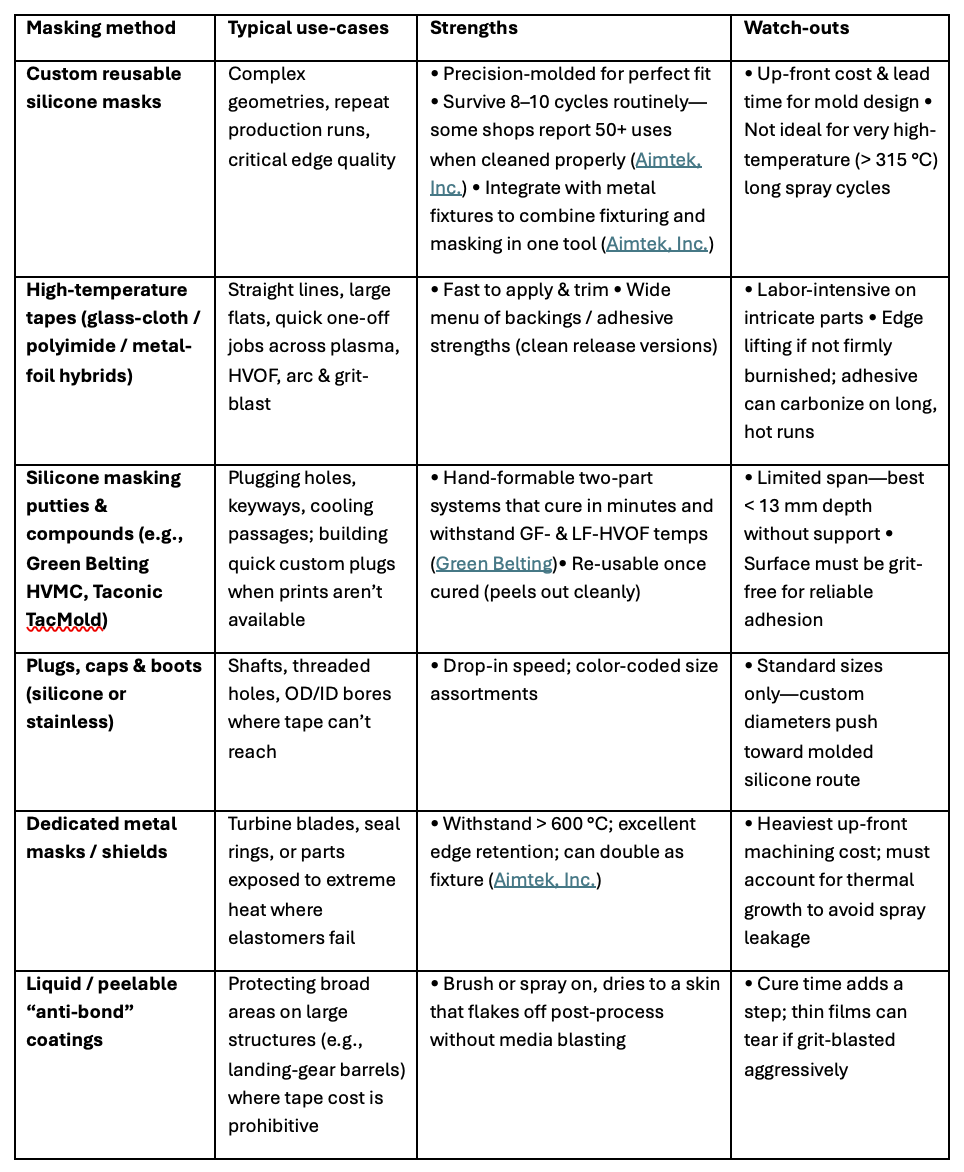

Quick-Guide: Masking Choices for Thermal Spray Shops

The following decision tree provides you with details without diving into brand specifics, yet the cited resources let you dig deeper if desired.

How to Choose

Temperature & erosion load – Plasma and HVOF demand the most robust materials; arc & flame spray allow lighter tapes and putties.

Part complexity & volume – High-mix/low-volume favors tapes and putty for flexibility; high-volume repeaters pay back quickly with molded silicone or metal masks.

Edge definition needs – Where coating over-run is intolerable (seal lands, threads), combine a hard stop (silicone mask or metal ring) with a sacrificial secondary layer of tape to catch overspray—standard practice for wide plumes in arc spray.

Down-stream cleaning budget – Reusable tooling slashes adhesive-removal labor; peelables minimize media blast touch-ups on large weldments.

Pro Tip: Many shops “stack” methods—e.g., silicone mask for the primary feature, HVMC putty in cooling holes, and fiberglass tape as secondary overspray shield—to balance cycle time, cost, and coating quality.

Remember, Thermach is not your competitor; your other options are. We don’t coat; we only supply thermal spray equipment and parts. You can proceed with confidence, knowing that our team is dedicated to creating a custom system that meets your exact specifications.

Manufacturer of Equipment & Parts for the Thermal Spray Industry. Backed by Reliable, Timely Service & Support.

Thermach manufactures thermal spray coating systems for the coating industry. We don't coat. We provide the equipment and parts necessary for you to run a successful coating operation. Our mission is to ensure your coating process is running smoothly with Thermach equipment.

Comments